Umuvuduko mwinshi upfa guta ni uburyo butuma ibyuma bisukuye cyangwa igice cyamazi cyuzuza umwobo wurupfu rwumuvuduko mwinshi hamwe numuvuduko mwinshi, kandi bigakomera kandi bigakomera mukibazo kugirango ubone casting.

1.Ibikorwa byo gutera hejuru

1.1

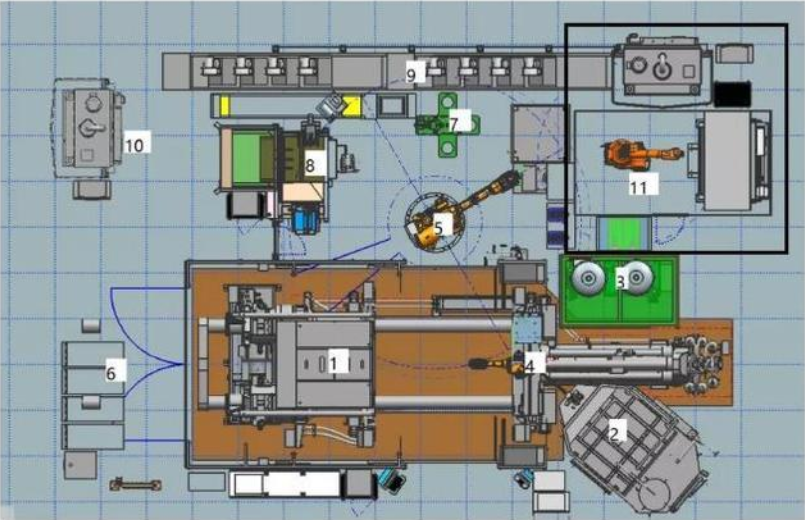

Kugeza ubu, ikirwa rusange cyo gupfa kizasuzuma ibice bikurikira; Imashini yo gupfa hamwe na vacuum, itanura ryo kubika ubushyuhe ifite sisitemu yo guta umubare, ibicuruzwa bifite ubwoko bwa sisitemu yo gutera, bigabanya igihe cyo gutera, robot yo gufata ibice, igikapu cya slag, gukata kode nindi mirimo, gukata kwanyuma kuri sisitemu y'irembo; Ikirwa cyo gupfa gishobora kandi kuzamurwa kugirango gikorwe mu buryo bwikora mu bihe byinshi.

1.2

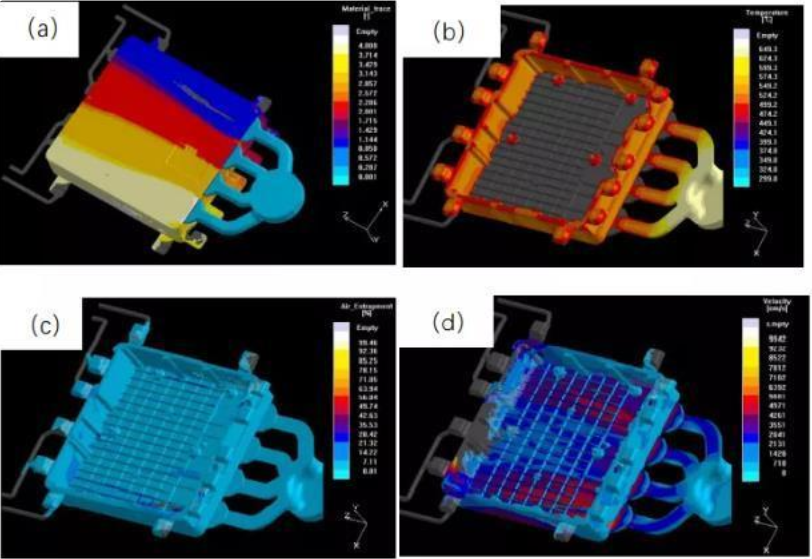

Isesengura rya CAE rirakoreshwa cyane mu nganda zipfa gupfa, zihagarariwe na PROCAST, MAGMA, flux-3D, nibindi. Ukurikije ibisubizo bibarwa byo kuzuza umuvuduko no gukwirakwiza umuvuduko, kwigana birashobora guhanura neza inenge nko kwiyandikisha, kubishyiramo no kuzuza nabi, bitezimbere cyane umusaruro kandi bizigama ikiguzi gifatika. Nigikoresho cyingirakamaro cyane muburyo bwihuse kandi bwa siyansi gushushanya sisitemu yose ya casting (irembo, amasoko na tank yuzuye, nibindi) kugirango bapfe. Kunoza ibipimo bya casting, kugabanya umubare wibizamini, kugabanya ibiciro bya casting, kuzamura ubwiza bwibicuruzwa. Porogaramu ya CAE yakoreshejwe mu gusesengura muri rusange kuzuza, gukomera, gukwirakwiza porotike na raporo yo gukwirakwiza umuvuduko

1.3 Gukoresha vacuum bipfa guta

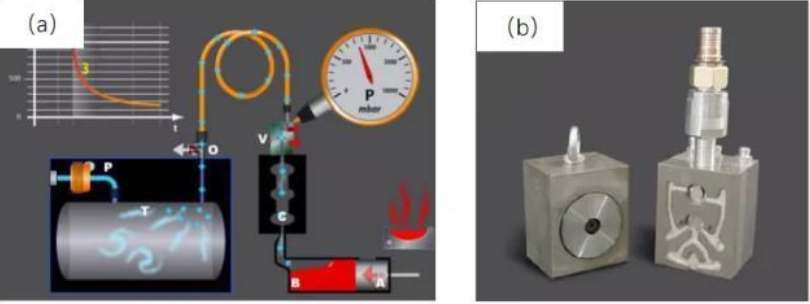

Hamwe nogukomeza gutanga ibicuruzwa byujuje ubuziranenge, gukoresha vacuum kugirango bikemure ikibazo cyo kuzuza no gukomera kwikirere cya casting byatejwe imbere neza, kandi na vacuum valve ikoreshwa muri rusange, valve ikunze gukoreshwa cyane ifite ibyiciro bibiri bikurikira. Igishushanyo cya 3 nigishushanyo mbonera cya vacuum. Kimwe nuburyo busanzwe bwo gupfa, nyuma ya aluminium yinjiye mucyumba, vacuumisation itangira gutangira. Noneho, iyo imashini itera gupfa itangiye kumuvuduko mwinshi, ingufu za kinetic yamazi ya aluminiyumu yishingikiriza kumasahani yisoko ya vacuum. Iyo ukoresheje imashini ya vacuum ya mashini, muri rusange iba ifunze mugihe ushyushye. Iyo preheating irangiye, valve vacuum irashobora gukoreshwa gusa mugihe umuvuduko mwinshi hamwe nigitutu byatangiye. Imashini ya vacuum ya mashini ifite ibyiza byo gukoresha byoroshye, ariko gutunganya neza neza vacuum ni byinshi, kandi ikiguzi cya vacuum ni kinini. Igishushanyo cya 4 nigishushanyo mbonera cya hydraulic vacuum valve. Ihame rya mashini ya vacuum yamashanyarazi nimwe. Iyo punch itangiye, vacuum iratangira, ariko ihame ryo gufunga valve vacuum iratandukanye. Iyo hydraulic vacuum valve itangijwe muri rusange ku muvuduko mwinshi, ubwoko bwoherezwa muri sisitemu ya hydraulic ya sisitemu ya vacuum icyarimwe, kandi valve ya vacuum ifunze. Igiciro cya hydraulic vacuum valve ni gito ugereranije, ariko birasaba ko ibipimo byo gupfa bipfa gushushanya hamwe nigishushanyo mbonera bigomba guhura, bitabaye ibyo amazi ya aluminiyumu apfa guta muri valve vacuum bizatera guhagarara.

2.Castings

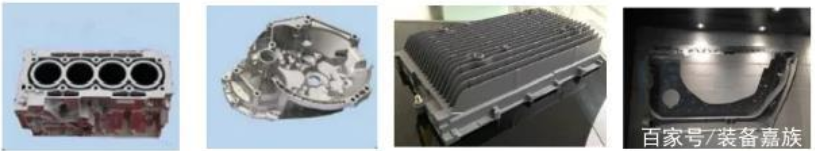

Kugeza ubu, aluminium alloy ipfa gukata igabanijwemo ibyiciro bitatu ukurikije umubare. Icyiciro cya mbere ni imodoka, ipikipiki, moteri yohereza moteri ihagarariwe na moteri ya moteri, umubiri wa silinderi nibindi. Ubwoko bwa kabiri ni sitasiyo ya sitasiyo na filteri igereranwa nu rusobe rwitumanaho, naho ubwoko bwa gatatu ni imiterere yumubiri hamwe nibisabwa byimikorere isabwa. Nkuko bigaragara ku gishushanyo, ni ibisanzwe bya aluminium alloy bipfa guta:

3.Umwanzuro

Aluminium alloy ifite imbaraga zidasanzwe kandi zirwanya ruswa, amashanyarazi meza. Mu mibereho yo kuzigama ingufu no kugabanya ibyuka bihumanya ikirere no kurengera ibidukikije, aluminium alloy die casting yateye imbere mu Bushinwa. Nizera ko mugihe cya vuba, ibicuruzwa bya aluminiyumu bizarushaho kuba byinshi. Ihinduka nyamukuru riri mubice bikurikira; 1) Hamwe niterambere ryibicuruzwa, bizateza imbere iterambere ryibikoresho bishya bipfa kwitwa aluminium alloy, nka: ubushyuhe bukabije bwumuriro, imbaraga nyinshi nicyerekezo gikomeye; ) .

Igihe cyoherejwe: Gicurasi-19-2022